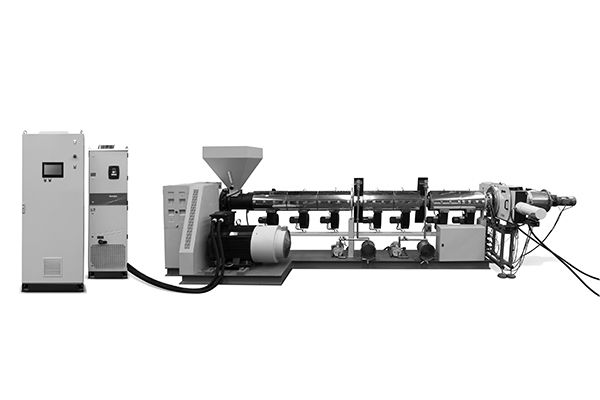

W kilku punktach chcieliśmy opisać zalety tej linii: Podwójny system stabilizacji temperatury w aglomeratorze, który składa się z dwóch dolnych […]

W kilku punktach chcieliśmy opisać zalety tej linii: Podwójny system stabilizacji temperatury w aglomeratorze, który składa się z dwóch dolnych […]

Bezpieczeństwo na każdym etapie procesu produkcyjnego oraz wysoka jakość wytwarzanych przez nas produktów, to dwa kluczowe aspekty, które przyświecają nam […]

Zapraszamy na 28. edycję targów "Fakuma" w dniach 17-21.10.2023 w Friedrichshafen w Niemczech. W tym roku pokażemy Państwu: nasze własne […]